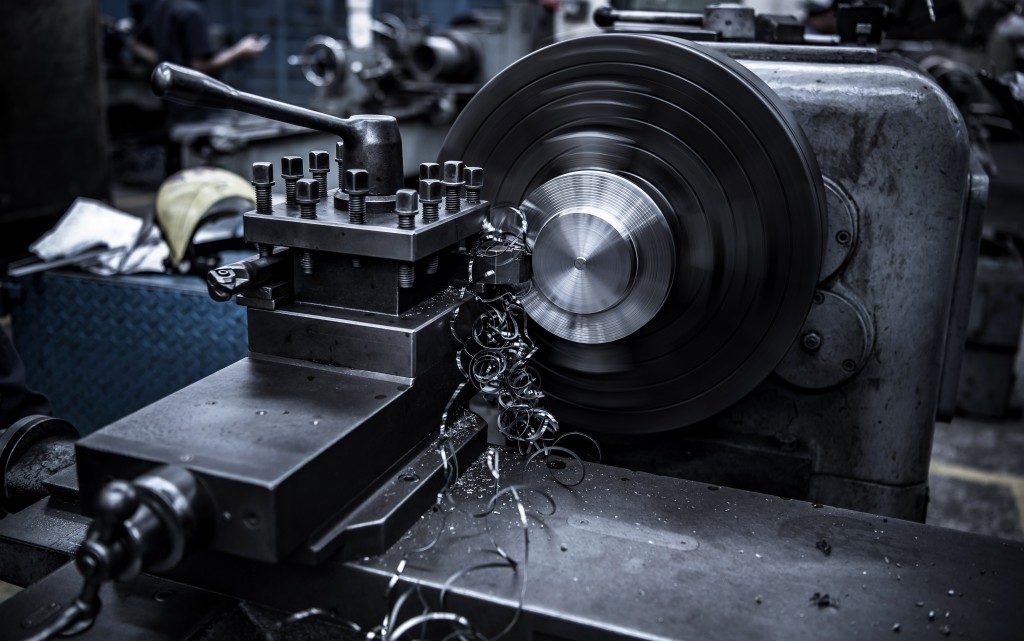

It is true that you can always buy other machines if yours fail. Since machines are costly, however, it is essential to take measures to extend their lifespan. Such measures also help avoid the inconveniences that come with downtime. If your machines operate at optimal efficiency, you are guaranteed of reduced costs, too. In case you would be selling the equipment in the future, caring for them appropriately increases their resale value. How can you extend the life of your machinery?

1. Maintain Them

Machinery maintenance helps minimize machinery repair costs. Most importantly, they help prevent breakdowns that can mean extensive damage and downtime. Conducting timely inspections and preventive maintenance practices is important. You ought to create a maintenance calendar for effective maintenance practices. A calendar ensures that all preventive maintenance tasks are done accordingly, especially if multiple operators use the machinery. You should work with reliable specialists in hydraulic machinery repair in Utah for inspection, maintenance, and repair services.

2. Conduct an Oil Analysis

Most people inspecting and maintaining machinery overlook oil analysis. Looking at samples of transmission, hydraulic, and engine oil helps identify issues before they become full-blown. This is because a proper analysis helps catch signs of contamination and wear and tear. You should be careful how you approach conducting such an analysis. Since the sample you take would represent all the oil in your device, you have to be careful when taking your sample. It is advisable to work with a reliable laboratory.

3. Train Your Operators

Maintaining your machinery would not be enough if your operators would abuse them. Understand that your employees’ skills are likely to become rusty with time. Keeping up training helps avoid a poor operation that might affect the lifespan of your machinery. Before entrusting your machines to a new operator, it is essential to train them whether they are seasoned or not. It is advisable to furnish all operators with simplified manuals for reference purposes.

Maintaining your machinery would not be enough if your operators would abuse them. Understand that your employees’ skills are likely to become rusty with time. Keeping up training helps avoid a poor operation that might affect the lifespan of your machinery. Before entrusting your machines to a new operator, it is essential to train them whether they are seasoned or not. It is advisable to furnish all operators with simplified manuals for reference purposes.

4. Avoid Engine Modification

Some operators ‘modify’ engines to acquire more power. The most common modification approaches include adding LP gas or alcohol injection, over-fueling, and turbo-charging. These modifications work sometimes. However, the demerits of boosting horsepower, particularly beyond standard ratings, outweigh the advantages. For instance, it reduces the lifespan of your engines significantly. If you have new machines, such modifications are likely to void the warranty.

5. Keep Your Machinery Clean

Neglecting cleaning large machinery is a bad idea. You should clean filters, seals, and breathers regularly. The electronics should also stay clean to operate at optimal efficiency. It is important not to use harsh cleaning products. Do not assume that cleaning idle machines is unnecessary. Be careful to store your machines well because dust, debris, snow, and other contaminants would damage them. It is advisable to erect a quality shed if you lack a building where you can store your machinery.

Neglecting your machines until something fails can mean reduced productivity and expensive repairs. You should also not assume that maintenance is unnecessary where machines come with extensive warranties. Where repairs are necessary, be careful to work with a reliable repair contractor.